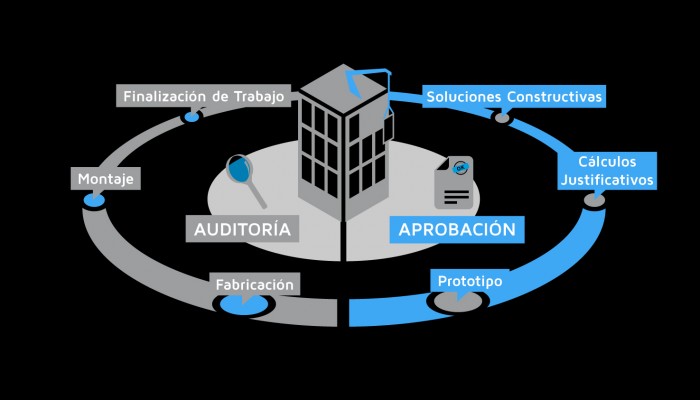

The “idea” has been developed and defined all its peculiarities and specific details before its implementation. The important thing is that during the execution not miss the spirit of the “idea” and respected the project developed, so the end result meets the specifications and desired qualities.

It is necessary to monitor and control the processes of designing specific solutions such as encounters between different facades, waterproofing and evacuations of water and drainage, building expansion joint systems, fire protection…

In the manufacturing, it is necessary to audit what is reflected in planes running on the workshop, controlling dimensional tolerances, vents and drains, sealed glass glued…

The prototype testing of the facade is paramount. This should be a true reflection of the entire envelope and the solution shown in planes and subsequently installed on site, should meet the minimum requirements required by the standard and that the property described in the tender documents.

The same workshop audit work should be performed in the site installation. So make sure that the fixings and welds do not show deficiencies in respect to what has been already calculated, that mounting tolerances allow dilate bodies, that evacuation systems are installed according to the projections, that the waterproof do not show installation deficiencies, etc.

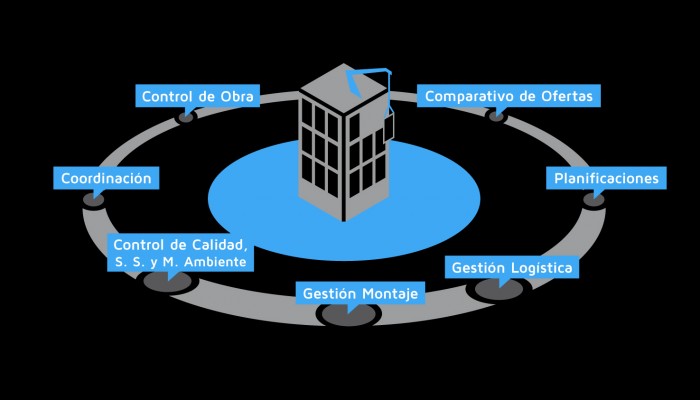

Who better than an Engineering – Consulting – Project Manager to take full responsibility for the proper execution of a coating? Renkho brings significant value to the market of envelopes, which is to put all his knowledge and experience at the service of control, monitoring and implementation. Renkho is not a facade company, but it can take full control of facade work, taking responsibility to Property, Architect and Builder for the implementation of the envelope of its site. Renkho does not have its own production facilities, but selects the best local companies to implement manufacturing processes and assembly solutions.

______________________________